sales02@visioninspection.com.cn

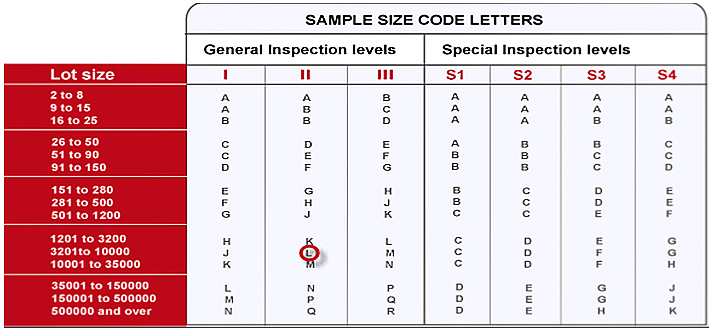

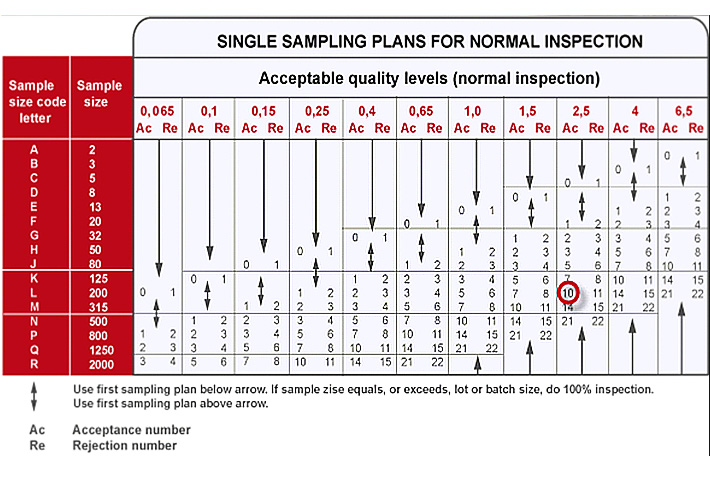

1.Sampling method:

Vision inspectors use MIL-STD-105 E form to sampling. These forms have already been recognized by every industrial company. This American standard corresponds with all domestic and international standards organization. This standard is a quite effective method, judging whether to accept or reject a production batch through the inspection of a randomly selected number of samples.( See the following forms)

stable A:

stable B :

2.AQL(Acceptable levels of quality):

Vision utilizes acceptable quality level (AQL), set the maximum allowable error rate or variable form standard.

Defect classification:

Defects in inspection are usually divided into three categories:

- Critical defects: Critical defect corresponds to a defect that may cause unsafe conditions to the end users. You can

provide your own check list of critical defect for checking.

The acquiescent critical defects AQL by Vision standard is 0.

- Major defects: This AQL is equivalent to any defects but doesn’t include critical defects. It could lead to failure of

product or reduce the availability of products. Major defects mean that: When it is not in danger, but the product cannot

be sold due to the existence of this defect. You can provide your own check list for major defects for inspection.

The acquiescent major defect AQL by Vision standard is 1.5.

- Minor defect: AQL corresponds to a defect for this item. As for the expected application, it will not reduce the

availability of products or departure from existing standards and exert little influence to effective use and operation of

products.But minor defect is the symbol that craft defects have exceeded the prescribed quality standards.

The acquiescent minor defect AQL by Vision standard is 4.0.

3. ISO9000 / ISO14000:

4. SA8000:

Consumers, customers and other shareholders becomes more and more concerned about whether the production of products accords with human rights, Child labor laws and non-discriminatory business activities.Published in Oct, 1997, social responsibility 8000 (or SA 8000) standard is the first global ethic moral standards, whose goal is to make sure fair purchasing and production for goods and service.

- Child labor: Company can't support the behavior of using child labors. Social responsibility international standard(SAI)

defines child labor as: Any workers younger than 15 years old, unless the local law for minimum age regulates an older

age for the workers.

- Compulsive workers: The company can't support the use of forced labor.

- Health and safety: The company must provide for its employees a safe and healthy working environment.

- Freedom of association and collective bargain rights: The company must respect rights of all employees

for choosing organization and join labor unions and collective bargaining.

- Discrimination: The company shall not be engaged in or support the discriminative behaviors in the aspects of

employment,compensation, participation in training, promotion, termination or retire on the basis of race, class, nationality,

religion, disability, gender,sexual orientation, union members, or political affiliation.

- Disciplinary measures: The company shall not be engaged in or support the use of corporal punishment, mental

or physical force or verbal threats.

- Work time: Company must abide by the applicable laws and standard of the industryin the work time issue.

- Remuneration: Company must ensure that wage payment for a cycle of standard working conforms to the laws

or the minimum standards for the industry.

- Management system: Top management team must establish company policy for social responsibility and labor

conditions to ensure that it meets all the requirements of this international standard and other relevant state laws and

regulations.